Noise measurement

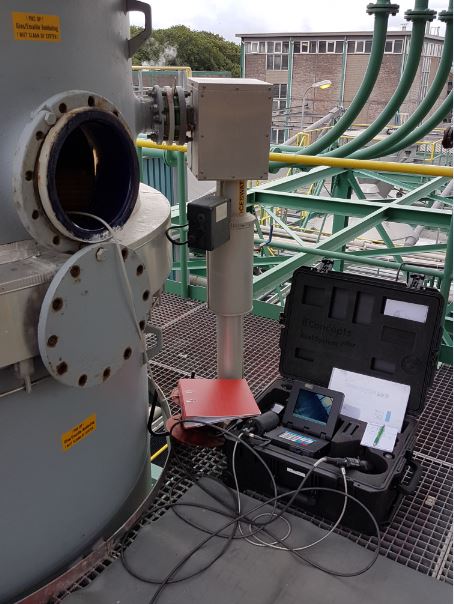

Dolphin Marine uses the SDT270 dectection device for this purpose, and this device offers all kinds of important innovations aimed at improving predictive maintenance programs. The SDT270 is designed by and for professionals. Not only is the SDT270 the first portable ultrasonic sensing device to include both a built-in temperature sensor and a laser tachometer, but it is also the first device to feature a built-in SQL database to capture and manage measurement data.

- Measures ultrasonic broadband signals with a bandwidth of 100 kHZ

- Collects data at a sampling rate of 250 kHz

- Uses long-term sampling and data streaming

- Integrates a built-in thermometer and tachometer with a laser

- Has a SQL database

- Ensures complete measurement traceability from user to sensor

- Alerts the user when an alarm is triggered

- Addressable via IP (Internet)

- Can be controlled and operated remotely

- Includes 2 measurement channels

Ultrasonic technology

Ultrasonic technology provides the most accurate solution for countless applications: tightness, leaks, electrical discharge and mechanical movement.

A good sounding solution

Technically, ultrasound is sound that cannot be heard by the human ear. In other words, sound with a frequency above 20 kHz. Ultrasound has a number of specific characteristics that make it useful in industrial applications. Ultrasound can be measured very accurately. Differences in intensity as the waves travel through a medium or body can be quantified. Thus, various phenomena that adversely affect the operation and quality of machines and systems can be clearly identified - often without interrupting their operation. High-frequency sounds are also more directional than those of lower frequency. This makes it easier to pinpoint the source, even with other background noise. The other big advantage of ultrasound is the huge number of things these ultrasonic signals produce. Leaks, strain, electrical discharges, cavitation (the appearance of imploding bubbles) in flowing fluids, turbulence in flowing gas or liquid; they all emit ultrasound that can be detected and measured.