Thermography / NEN inspection

The care for safe installations imposed on all employers by the Occupational Health & Safety Act requires them to carry out NEN-EN 50110 & NEN 3140 safety inspections. Dolphin can perform these inspections for you in combination with thermographic inspection. Both inspections focus on safety and operational reliability of electrical installations. It is sometimes wrongly thought that the de-energized measurements from NEN 3140 can be replaced by performing a thermographic inspection.

Thermographic inspection (NEN inspection)

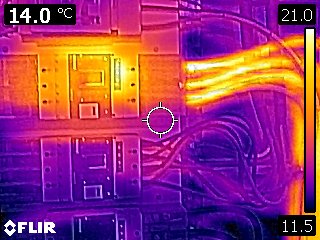

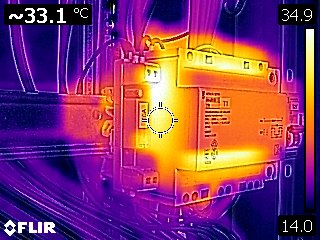

Thermographic inspection (NEN inspection) is a method of examining the fire safety and operational reliability of process or mechanical installations. Perhaps the most imaginative prevention application is the prevention of fire in electrical installations by thermographic "scanning" of switchgear and distribution devices. It should be remembered, however, that the inspection is a snapshot of the installation in question. Periodic repetition of the thermographic inspection is therefore necessary if the importance of the preventive nature of the inspection has been recognized.

It is also not for nothing that many property-casualty insurers require the insured to periodically inspect (or have inspected) electrical systems thermographically.

The benefits in terms of fire safety are obvious, but there are also many gains to be made in terms of operational reliability using thermography. A periodic performance has a preventive effect that helps you with your maintenance task on the one hand and fulfills your health and safety legal responsibilities on the other.

What does a thermographic inspection involve?

A thermographic inspection involves determining the temperature of the objects or objects to be examined. This allows the temperature of a surface or part to be determined in an extremely fast and adequate manner. During the inspection, a thermographic photograph and, as a reference source, a normal digital color photograph of the object under investigation are taken. A very important advantage of "scanning" with a thermographic system is that the measurement is made without direct contact between the object being examined and the measuring system. This makes the system ideally suited for measurements on hard-to-reach or live objects or objects in hazardous environments. An added benefit is that there is no product stagnation.