Vibration Analysis

Vibration analysis finds many applications in performing the various maintenance tasks. Since vibration analysis is a highly specialized technique, which many companies will outsource, it is important to offer a complete concept.

Trouble Shooting

Detecting problems in running machines quickly and efficiently is what is meant by trouble shooting. When a machine makes "strange" noises, or a machine monitoring system indicates high (vibration) values, one wants to know the cause of this as soon as possible. By performing a vibration measurement, without having to take the machine apart, the condition of the various components can be determined. This will reveal any defects, making it possible to target the required maintenance action(s).

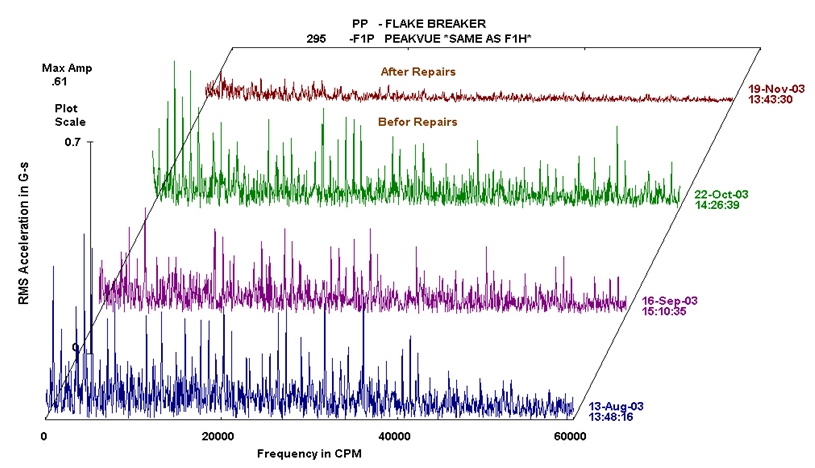

Trend monitoring

Trend monitoring is used as part of a preventive maintenance program. By recording the vibration behavior of rotating machinery at regular intervals, wear and aging behavior can be identified. For example, these measurements are taken 4 to 6 times a year. By comparison with prior measurements, it is possible to determine with a high degree of certainty whether certain defects are occurring and at what times these defects lead to exceedance of the established limit. Thus, maintenance becomes more manageable and follow-up damage or machine failure can be greatly reduced. Because trouble shot and trend measurements will need to be entered at different clients, an easily portable data collector/analyzer will be used.

Balancing

Balancing is a less specialized technique compared to vibration analysis This is because balancing uses special balancing programs, which greatly simplify balancing a machine. Companies nevertheless often outsource this technique. People choose to outsource because the investment in equipment and training is not worthwhile in proportion to the number of performances of balancing in practice.

For balancing a machine, companies can choose from two options:

On-line balancing

On-line balancing will take place on a balancing bench, with the part to be balanced having to be moved to this bench. This involves complex balancing across multiple planes.

Off-line balancing

Off-line balancing will take place on-site at the machine and will focus primarily on single plane balancing and two plane balancing.

Overall Measurements

The decision to repair may come about when the overall vibration level has risen above a certain values (standard). Standards for machines have been developed by the ISO and VDI, with groups of machines classified by power. Using these standards, one can determine, using a group catogory classification , whether the machine condition is still good, serviceable, still permissible or impermissible. Measuring an overall value has the advantage that the measurement techniques used are easy to perform. However, a disadvantage of these standards is that they are measured within a small frequency range (10- 1000Hz).

Overall measurements should be seen as an initial indication of machine condition. A quick overview of the general condition of the machine can be obtained with a limited number of measurement data. This can be compared to a temperature, blood pressure, pulse reading at the doctor's office. This measurement technique is mainly used in trend measurement and is also a starting indication for "troubleshooting." Another important advantage over the way it was done before (without vibration measurement equipment) is that it now works with a number. This is obvious and recognizable to anyone, but when measurement with a screwdriver indicates that it can still be done, it is difficult to give reproducible advice, or to transfer this knowledge.

FFT: Fast Fourier Transformation

An overall measurement of the vibration signal indicates in a value the magnitude of the vibration signal without distinguishing between the different frequencies that make up the signal. This measurement cannot then provide information regarding the cause of the vibrations. Frequency analysis does allow a statement about the cause of the vibration. Indeed, frequency components can be related to machine components. This works as follows: the measured signal from the time domain is converted to the frequency domain using Fourier Transform (FFT). In this way, the time signal is divided into a series of sinusoidal signals, which are represented in the frequency spectrum as vertical lines with their own frequency and vibration amplitude. It is now possible to evaluate the condition of individual machine components and recognize defects at an early stage. In this way, corrective actions can be taken in time. This principle can be compared to a hospital x-ray. This measurement technique is used for both trend measurement and "trouble-shooting."